Wind Energy: High-Performance Bearings in Modern Turbines

2026-01-16In the search for clean energy options, wind power plays a big role in producing electricity from natural wind. The bearing systems sit at the heart of wind turbine reliability and good performance. These parts work in tough situations. They hold up huge structures and face changing forces, different speeds, and hard surroundings. New progress in bearing tech aims to raise load handling, cut down on wear, and make service life longer. This helps meet the rising needs of the wind energy field.

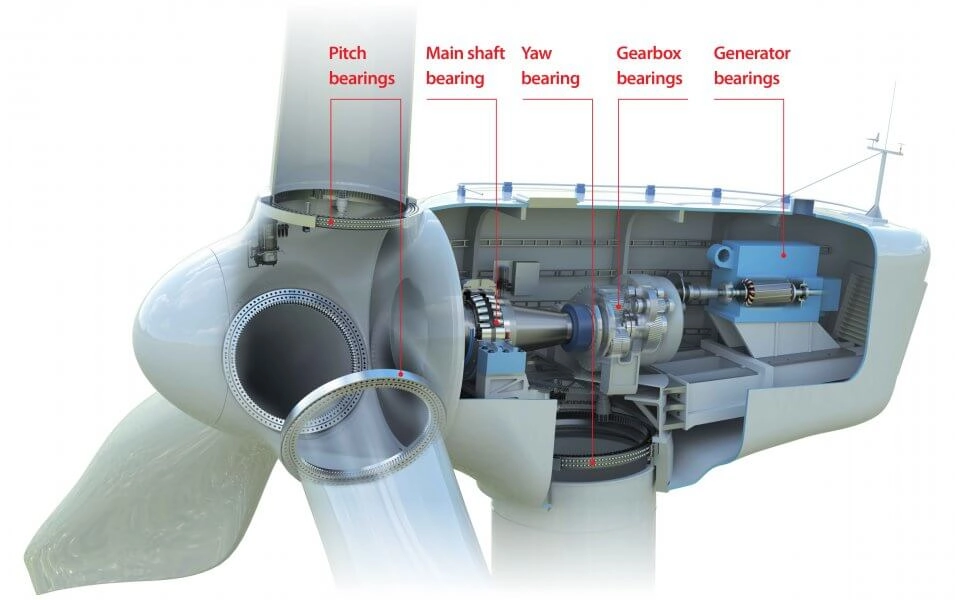

Wind Turbine Bearings

Wind turbines use several kinds of bearings to deal with various mechanical jobs and loads in the whole system. The main groups include:

Mainshaft Bearings

These sit in place to hold the main shaft that connects the rotor hub to the gearbox. They take on large axial and radial loads from wind bursts and the weight of the rotor. Designs often use spherical roller bearings, tapered roller bearings, or cylindrical roller bearings. The choice depends on the turbine setup to give the best results under heavy and shifting stresses.

Pitch and Yaw Bearings

Pitch bearings let the blades change angle to catch more energy from changing wind. Yaw bearings let the nacelle turn to face the wind direction. These parts usually have slewing bearings, spherical roller bearings, or double-row ball bearings. They handle frequent but smaller movements and loads.

Generator Bearings

These support the generator shaft as it spins. They manage forces tied to making electricity. Common types include cylindrical roller bearings, deep groove ball bearings, and angular contact ball bearings. Each fits the generator’s rotation and load needs.

Gearbox Bearings

These matter a lot for sending power from the rotor to the generator. Gearbox bearings face high speeds and torques. Setups often include cylindrical roller bearings, spherical roller bearings, or tapered roller bearings. It depends on the gearbox size and design details.

Support and Auxiliary Bearings

Smaller bearings hold secondary parts like cooling fans, brakes, and hydraulic units. These use ball bearings, roller bearings, or special types to match exact needs.

Together, these bearing kinds keep the turbine running smoothly. They turn wind’s kinetic energy into steady electrical power. Ongoing engineering work looks to improve lasting power, lower maintenance needs, and raise overall system efficiency in wind power setups.

Challenges in Wind Turbine Bearings

Bearings in wind turbines face very hard working demands. These test material limits and design strength. Main issues include:

-

High Loads: They hold heavy rotor parts plus changing forces from wind. This causes a lot of fatigue, faster wear, and possible early breakdown if not handled right.

-

Harsh Environmental Conditions: Turbines sit in extreme places, from dry deserts to freezing cold areas. Bearings meet big temperature changes, moisture, and dirt particles. These lead to rust and breakdown over time.

-

Maintenance and Downtime: Offshore sites or far-away land spots, plus the large turbine size, make checks and fixes hard. The resulting downtime brings big money losses and less energy output.

These points show the clear need for strong bearing answers. They must give steady performance in real wind farm settings.

Innovations in Bearing Designs

The wind energy field puts a lot of effort into bearing improvements. The goal is to reduce problems and make turbines last longer. Key new steps include:

-

Multi-Row Bearings: Spreading load over several rows of rolling elements lowers stress on each part. This raises capacity and makes life longer under very heavy loads.

-

Enhanced Lubrication Systems: New lubricant mixes, including solid types and smart oil flow, cut friction and wear. They also extend service times even when dirt or temperature shifts happen.

-

Integrated Sensors and Condition Monitoring: Bearings now come with built-in sensors. These give real-time data on vibration, temperature, and load changes. This allows predictive maintenance steps that stop failures before they happen and keep uptime high.

-

Advanced Materials: Using ceramics, special steel mixes, and other strong substances boosts resistance to fatigue, rust, and wear. This gives better reliability.

-

Sealing Solutions: Better seal setups block dust, water, and debris from getting in. They protect inside parts and greatly lengthen bearing life in bad conditions.

These changes together help lower running costs and raise trust in energy output.

Future Perspectives

Wind energy keeps growing. This pushes more changes in bearing tech. New paths ahead include:

-

Adding nanotechnology to build super-strong materials with better strength and lasting power.

-

Ideas for self-lubricating and self-healing bearings to greatly reduce maintenance work.

-

Using machine learning and AI methods for better predictive checks. These improve maintenance plans and raise turbine availability.

These upcoming steps point to bearings that handle tough conditions much better. They support wind power’s part in cutting global carbon emissions.

Wind turbine bearings form a key but difficult piece in renewable energy setups. Through steady new work on load control, weather resistance, and smart tracking, the field moves toward more reliable and cheaper wind power. As wind farms grow around the world, high-performance bearings stay vital. They unlock higher efficiency and sustainability in clean energy making.

LQYS Bearings

LQYS Bearings, as a professional manufacturer and seller of high-precision bearings including spherical roller bearings, cylindrical roller bearings, tapered roller bearings, and other types suitable for demanding applications, offers reliable solutions for wind energy projects. With advanced production processes and modern testing equipment, LQYS Bearings supports industries such as renewable energy with quality products designed for performance and longevity. Manufacturers and sellers in the wind turbine sector can explore customized bearing options to meet specific project requirements.

FAQ

What are the main types of bearings used in wind turbines?

Wind turbines use mainshaft bearings (often spherical, tapered, or cylindrical roller types), pitch and yaw bearings (frequently slewing or double-row ball designs), generator bearings (cylindrical roller, deep groove ball, or angular contact), gearbox bearings (spherical, cylindrical, or tapered roller), and various auxiliary support bearings.

Why do wind turbine bearings face high failure risks?

Extreme loads from rotor weight and changing wind, plus tough weather and hard access for fixes, lead to fatigue, corrosion, and wear. These can cause early problems.

How do modern innovations improve wind turbine bearing performance?

Multi-row setups, better lubrication, sensor add-ons for checks, stronger materials, and improved seals all help handle loads, lower friction, support predictive fixes, and extend life.

What future technologies may impact wind turbine bearings?

Nanomaterials for tougher parts, self-lubricating and self-healing ideas, and AI-based predictive tools should cut maintenance a lot while raising reliability and efficiency.

Partner with LQYS Bearings – Manufacturer and Seller of High-Performance Bearings

For wind turbine manufacturers, OEMs, project developers, and suppliers seeking dependable bearing solutions, LQYS Bearings provides high-quality, precision-engineered bearings tailored to renewable energy demands. Contact the team today via email at salesjake@lqysbearing.com, phone at +8613002187311, or WhatsApp at +8618013237311 to discuss custom specifications, request quotes, or explore how LQYS Bearings can support turbine reliability and project success.