উচ্চ গতির ট্রান্সমিশন বিয়ারিং: মসৃণ গিয়ার শিফট এবং দীর্ঘজীবন নিশ্চিত করা

2025-10-24

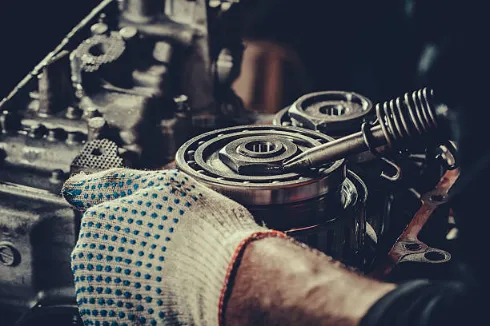

আজ’ দ্রুত গতির অটোমোবাইল বিশ্ব, ট্রান্সমিশন আগে কখনও সীমা চালানো. উচ্চ গতির ট্রান্সমিশন বিয়ারিং সবকিছু মসৃণ চলছে। তারা তীব্র লোড এবং গতি পরিচালনা করে, গিয়ার শিফট সহজ অনুভব করে।

আধুনিক ট্রান্সমিশনে বিয়ারিংয়ের ভূমিকা

ট্রান্সমিশন বিয়ারিং আসলে কি করে

ট্রান্সমিশন বেয়ারিং ঘূর্ণমান শাফ্টগুলিকে সমর্থন করে যা প্রতিদিন টর্ক এবং গতির সাথে মোকাবিলা করে। তারা গিয়ারবাক্সের ভেতরে ঘর্ষণ এবং তাপ কাটিয়ে দেয়। তাদের ছাড়া অংশগুলি একে অপরের বিরুদ্ধে গ্রাইন্ড হবে, যার ফলে দ্রুত ভেঙে যাবে। এই বেয়ারগুলি একটি সেতুর মতো কাজ করে, ভারী লোড বহন করার সময় উপাদানগুলিকে মুক্তভাবে চলতে দেয়।

নিন থ্রাস্ট বেয়ারিংউদাহরণস্বরূপ। অক্ষীয় বেয়ারিং নামেও পরিচিত, তারা মূলত শাফ্টের সমান্তরাল শক্তি পরিচালনা করে। রেডিয়াল বিয়ারিংয়ের বিপরীতে যা পাশের লোড গ্রহণ করে, থ্রাস্ট বিয়ারিংগুলি অক্ষীয় বা থ্রাস্ট লোডে তারা ঘূর্ণমান যন্ত্রপাতিতে স্থির অপারেশন নিশ্চিত করে। প্রায়শই অটোমোবাইল ট্রান্সমিশন, ক্লাচ, ফ্যান, পাম্প এবং কম্প্রেসারে পাওয়া যায়। থ্রাস্ট বেয়ারিং একটি হাউজিংয়ে বল বা রোলার ব্যবহার করে, সবকিছু জায়গায় রাখতে একটি খাঁচা সহ।

কেন উচ্চ গতির অ্যাপ্লিকেশনগুলি নির্ভুলতার চাহিদা

আধুনিক ট্রান্সমিশনগুলি আরও কঠোর সহনশীলতার সাথে উচ্চতর আরপিএমতে ঘূর্ণিত হয়। এর মানে হচ্ছে বিয়ারিংগুলিকে অবশ্যই স্পটে থাকতে হবে। যে কোনও ঘূর্ণন ভারসাম্যহীনতা গিয়ার শিফটকে বিশৃঙ্খল করত সঠিকতা হয়’ টি শুধু সুন্দর, it’ পারফরম্যান্সের জন্য অপরিহার্য। রেসিং গাড়ি বা বৈদ্যুতিক গাড়ি সম্পর্কে চিন্তা করুন; একটি ছোট ত্রুটি বড় সমস্যা সৃষ্টি করতে পারে। এবং হ্যাঁ, কখনও কখনও প্রকৌশলীরা উপেক্ষা করে কিভাবে উচ্চ গতির তাপ জিনিসগুলিকে বিকৃত করে, কিন্তু তাড়াতাড়ি

সাধারণ ভারবহন টাইপ ট্রান্সমিশন ব্যবহৃত

বল বেয়ারিং, রোলার বেয়ারিং এবং সুই বেয়ারিং ট্রান্সমিশনে অনেক দেখায়। প্রত্যেকটির তার শক্তি লোড এবং ডিজাইনের প্রয়োজনীয়তার উপর ভিত্তি করে।

বল বেয়ারিং অনেক সেটআপের জন্য যান। তাদের অভ্যন্তরীণ এবং বাইরের রিং এর মধ্যে বল রয়েছে যার মধ্যে আর্ক আকৃতির খাঁজ রয়েছে। এই রেডিয়াল লোড, উভয় দিকে অক্ষীয় লোড, বা একটি মিশ্রণ পরিচালনা করে। উচ্চ গতির ঘূর্ণনের জন্য দুর্দান্ত। কিছু গ্রিস দিয়ে প্রাক ভরা হয় বা সিল রয়েছে, যা হাউজিং ডিজাইনকে সহজ করে। ঘর্ষণ কম কারণ বল স্লাইড পরিবর্তে রোল। কিন্তু সময়ের সাথে সাথে, বল ভারী চাপের অধীনে সমতল হতে পারে, তাই নিয়মিত রেটিং পরীক্ষা করুন।

রোলার বেয়ারিং আরও বেশি দায়িত্বের জন্য পদক্ষেপ নিন। সিলিন্ডার রোলার বেয়ারিংউদাহরণস্বরূপ, রোলিং উপাদান হিসেবে সিলিন্ডার ব্যবহার করুন। তারা বাইরের রিংগুলিতে রৈখিক যোগাযোগের সাথে বিশাল রেডিয়াল লোডকে সমর্থন করে, একটি বিস্তৃত এলাকায় শক্তি ছড়িয়ে দেয়। বায়ু টারবাইন বা খনির সরঞ্জামের মতো ভারী যন্ত্রপাতির জন্য নিখুঁত। এন এবং এনইউ এর মতো প্রকারগুলি অক্ষীয় স্থানান্তর অনুমতি দেয়, যখন এনজে এবং এনইউপি থ্রাস্ট লোডও পরিচালনা করে। তারা বল বেয়ারিংয়ের চেয়ে ক্লান্তি এবং শক প্রতিরোধ করে। মাউন্ট করা সহজ এবং তারা চরম পরিস্থিতিতে কাজ করে।

সুই বেয়ারিং সুইকের মতো পাতলা, দীর্ঘ রোলারগুলির সাথে একটি ধরনের রোলার ভারবহন। তারা ছোট জায়গায় উচ্চ লোড ক্ষমতা প্যাক করে। বল বা স্ট্যান্ডার্ড রোলার বেয়ারিংয়ের তুলনায়, সুইগুলি আরও পৃষ্ঠ এলাকার সাথে যোগাযোগ করে, একই শাফ্ট আকারের জন্য 2 থেকে 8 গুণ লোড পরিচালনা করে। কম্প্যাক্ট ডিজাইনের জন্য আদর্শ, যেমন কম্প্রেসার বা ইঞ্জিন সংযোগের রডগুলিতে। তারা ভিন্ন গতি বা দুর্বল তৈলাক্তকরণ সহ দোলনমান গতি এবং কঠোর পরিবেশের উপযুক্ত। সাধারণত এই সহ রোলিং বেয়ারিংগুলির কম প্রারম্ভিক ঘর্ষণ, সহজ স্যুপগুলির জন্য স্ট্যান্ডার্ড আকার রয়েছে এবং রেডিয়াল এবং অক্ষীয় উভয় লোড গ্রহণ করতে পারে। তারা বিশেষ করে উচ্চ বা কম তাপমাত্রায় দক্ষতার ক্ষেত্রে সাদা বেয়ারগুলিকে পরাজিত করে।

ট্রান্সমিশন বিয়ারিং দ্বারা মুখোমুখি চ্যালেঞ্জ

চরম অপারেটিং শর্তাবলী

ট্রান্সমিশনে বিয়ারিং নিষ্ঠুর অবস্থার মুখোমুখি। উচ্চ গতি, পরিবর্তনশীল টর্ক এবং তাপমাত্রা সুইং ধ্রুবক থাকে। এছাড়াও, তৈলাক্তকরণ সময়ের সাথে সাথে ভেঙে যায় বা দূষিত হয়। এটা’ খারাপ আবহাওয়াতে ম্যারাথন দৌড়ার মতো, সবকিছু দ্রুত পরে। অক্ষীয় লোডের জন্য নির্মিত থ্রাস্ট বেয়ারিংগুলি এখনও সংগ্রাম করে যদি তাপ খুব বেশি হয়।

মাইক্রো কম্পন এবং শব্দের সমস্যা

গিয়ার মেশিং বিয়ারিংয়ের মধ্যে প্রতিধ্বনি তৈরি করে। ক্ষুদ্র অক্ষমতা মাইক্রো স্তরে কম্পন বৃদ্ধি করে। এটি এমন শব্দের সৃষ্টি করে যা ড্রাইভাররা ঘৃণা করে। উচ্চ গতির সেটআপ, এটি’ আরো খারাপ; কম্পন পুরো সিস্টেমকে ঝাঁকিয়ে দিতে পারে। কখনও কখনও ’ শুধু ভারবহন নয়, তেলের ময়লা বাজে যোগ করে। জিনিসগুলো পরিষ্কার রাখা একটি টন সাহায্য করে।

সময়ের সাথে সাথে পরিধান এবং ক্লান্তি

পিটিং এবং স্প্যালিং সাধারণ পোশাকের সমস্যা। তারা পৃষ্ঠে চিপ দূর করে, পারফরম্যান্স ক্ষতিগ্রস্ত করে। দুর্বল তৈলাক্তকরণ এটি দ্রুত করে, প্রাথমিক ব্যর্থতার কারণ। রোলার বেয়ারিং তাদের নকশার কারণে ভালভাবে ধরে রাখতে পারে, কিন্তু এমনকি তারা ক্রমাগত চাপের অধীনে ক্লান্তি। নিয়মিত পরীক্ষা তারা ট্রান্সমিশন ধ্বংস করার আগে এগুলি সনাক্ত করে।

উচ্চ গতির পারফরম্যান্সের জন্য প্রকৌশল উদ্ভাবন

উন্নত উপকরণ এবং তাপ চিকিত্সা

উচ্চ বিশুদ্ধতা ইস্পাত বিয়ারিং ক্লান্তি প্রতিরোধের বৃদ্ধি। তাপের চিকিৎসা তাদের আরও কঠোর করে তোলে। সিরামিক হাইব্রিডগুলি উচ্চ গতিতে স্থিতিশীলতা যোগ করে। এই সামগ্রীগুলো পোশাকের উপর কাটা হয়। জন্য সিলিন্ডার রোলারএর মানে হচ্ছে ঘাম ভেঙে না শক লোড পরিচালনা।

তৈলাক্তকরণ অপ্টিমাইজেশন

বিশেষ তেল এবং গ্রিস একটি বড় ভূমিকা পালন করে। তারা একটি ফিল্ম তৈরি করে যা ঘর্ষণ তাপ প্রতিরোধ করে। ট্রান্সমিশনে, সঠিক বেধ অংশগুলিকে শীতল রাখে। তাদের সামান্য আকারের সাথে সুই বেয়ারিংগুলি তাদের সংকীর্ণ স্থানে উপকৃত হয়। কিন্তু যদি তেল নোংরা পায়, এটি’ খেলা শেষ, দূষণ সবকিছু ধ্বংস করে।

নির্ভুলতা উত্পাদন এবং মাইক্রো সহনশীলতা নিয়ন্ত্রণ

সিএনসি গ্রাইন্ডিং রেসওয়ে সুপার মসৃণ নিশ্চিত করে। সারফেস ফিনিশিং এবং টাইট সহনশীলতা সবকিছু নিয়ন্ত্রণ করে। শাফ্ট সারিবদ্ধতা এবং প্রিলোড নির্ভুলতাও বিষয়। বল বেয়ারিং এখানে কম ঘর্ষণের সাথে উজ্জ্বল হয়, কিন্তু ভারী লোডের জন্য রোলারগুলির সেই নির্ভুলতার প্রয এটা’ সবকিছু ভারসাম্য নিয়ে।

মসৃণ গিয়ার শিফট নিশ্চিত করা: ভারবহনের লুকানো ভূমিকা

গিয়ার এবং শাফ্টগুলির মধ্যে ঘর্ষণ হ্রাস করা

মসৃণ বেয়ারিং পরিবর্তনগুলিকে দারুণ অনুভব করে তোলে। তারা ধারাবাহিক অক্ষীয় সমর্থন প্রদান করে। ঘর্ষণ ড্রপ, তাই গিয়ার এবং শাফ্টগুলি সহজেই চলে যায়। থ্রাস্ট বেয়ারিং এখানে সাহায্য করে, স্থিতিশীলতার জন্য অক্ষীয় লোড নিয়ন্ত্রণ করে। কম ঘর্ষণ ছাড়া, শিফটগুলি ক্ল্যাঙ্কি হয়ে যায়।

গিয়ার স্লিপেজ এবং কঠোর পরিবর্তন প্রতিরোধ

বেয়ারিং কঠোরতা এবং ক্লিয়ারেন্স টর্ক স্থানান্তর প্রভাবিত করে। নির্ভুলতা সঠিক সময় পরিবর্তন রাখে। সিলিন্ডার রোলারগুলি, তাদের রেডিয়াল লোড সমর্থনের সাথে, উচ্চ টর্ক মুহূর্তে স্লিপ প্রতিরোধ করে। এটা’ স্বয়ংক্রিয় বা ম্যানুয়াল একইভাবে গুরুত্বপূর্ণ।

শব্দ, কম্পন এবং কঠোরতা (এনভিএইচ) নিয়ন্ত্রণ

প্রকৌশলীরা বাস্তব বিশ্বের সিমুলেশন দিয়ে এনভিএইচ পরীক্ষা করে। কম ঘর্ষণ বেয়ারিং ড্রাইভার অস্বস্তি কাটানো। কম্পন ড্যাম্পিং যেমন কৌশল সাহায্য করে। সুই বেয়ারিং দোলনমান অংশগুলিতে নিষ্ক্রিয়তা হ্রাস করুন, জিনিসগুলি শান্ত করুন। একটি মসৃণ রাইড শুরু হয় শান্ত বিয়ারিং দিয়ে।

স্মার্ট ডিজাইন এবং রক্ষণাবেক্ষণের মাধ্যমে ভারবহন জীবনকাল প্রসারিত করা

সঠিক ইনস্টলেশন এবং সারিবদ্ধতা

দ্রুত পরিধান এবং তাপ দ্রুত। সমাবেশের জন্য সেরা অনুশীলন অনুসরণ করুন। সঠিকভাবে সমস্যা এড়াতে পারেন। রোলার বেয়ারিং সহজে মাউন্ট করে, কিন্তু এটি ভুল করুন এবং জীবনকাল ড্রপ।

নিয়মিত তৈলাক্তকরণ এবং তেল পরিষ্কার

পরিষ্কার তৈলাক্তকরণ দূষণ বন্ধ করে। ফিল্টার এবং পরিবর্তন চক্র গুরুত্বপূর্ণ। বল বেয়ারিং, তাদের সঙ্গে সীল বিকল্পকিন্তু যেকোনোভাবেই পরীক্ষা করুন। ভালো তেল জীবন বড় সময় বাড়ায়।

প্রাথমিক ব্যর্থতা সনাক্তকরণ

শব্দ শুনুন, কম্পন অনুভব করুন, তাপ পরীক্ষা করুন। কম্পন বিশ্লেষকের মতো সরঞ্জামগুলি সমস্যাগুলিকে তাড়াতাড়ি সনাক্ত করে। থ্রাস্ট বেয়ারিংয়ের মধ্যে স্প্যালিং ধরা পুরো সেটআপটি সংরক্ষণ করে।

উচ্চ গতির ট্রান্সমিশন বিয়ারিং বিশেষজ্ঞ

উচ্চ আরপিএম পরিবেশের জন্য যথার্থ প্রকৌশল

ইয়ংহেশুন নির্ভুলতা এবং পৃষ্ঠের মানের উপর মনোনিবেশ করে। তাদের বেয়ারগুলি উচ্চ আরপিএমগুলিকে অস্থির ছাড়াই পরিচালনা করে। উৎপাদন নিয়ন্ত্রণ শীর্ষ পারফরম্যান্স নিশ্চিত করে।

কঠোর সহনশীলতা এবং এনভিএইচ পরীক্ষা

পরীক্ষাগুলি প্রকৃত লোড, গতি এবং তাপের অনুকরণ করে। এটি বাজারের আগে সমস্যা সৃষ্টি করে। এনভিএইচ চেক জিনিসগুলি শান্ত এবং মসৃণ রাখে।

OEM এবং Aftermarket প্রয়োজন জন্য কাস্টমাইজড ভারবহন সমাধান

ইয়ংহেশুন অটো, ইভি এবং ভারী গিয়ারের জন্য তৈরি করা বিকল্প সরবরাহ করে। OEM বা aftermarket, তারা নির্দিষ্ট ট্রান্সমিশন প্রয়োজনীয়তা ফিট।

উপসংহার

উচ্চ গতির ট্রান্সমিশন বেয়ারিং শিফটগুলিকে মসৃণ এবং সিস্টেমগুলিকে নির্ভরযোগ্য করে তোলে। নির্ভুলতা, স্মার্ট তৈলাক্তকরণ এবং উপাদানের অগ্রগতি এটিকে চালায়। ইয়ংহেশুন একটি নির্ভরযোগ্য নির্মাতা হিসাবে দাঁড়িয়ে আছে, টেকসই সমাধান সরবরাহ করে যা স্থায়ী।

সাধারণ প্রশ্ন

প্রশ্ন 1: ট্রান্সমিশনগুলিতে প্রধান ধরণের বিয়ারিং কি?

সাধারণ বেশি উচ্চ গতির, কম ঘর্ষণ প্রয়োজন জন্য বল বেয়ারিং অন্তর্ভুক্ত; ভারী রেডিয়াল লোডের জন্য সিলিন্ড্রিক মত রোলার বেয়ারিং; এবং কম্প্যাক্ট, উচ্চ লোড স্পেস জন্য সুই বেয়ারিং।

প্রশ্ন 2: কিভাবে থ্রাস্ট বিয়ারিং রেডিয়াল থেকে পৃথক হয়?

থ্রাস্ট বেয়ারিং শাফ্টের সমান্তরাল অক্ষীয় লোড পরিচালনা করে, যখন রেডিয়াল বেয়ারিং উল্লম্ব শক্তি গ্রহণ করে। থ্রাস্ট টাইপগুলি একক বা দ্বৈত দিকে আসে।

প্রশ্ন 3: কেন উচ্চ গতির ট্রান্সমিশনে বিয়ারিং ব্যর্থ হয়?

প্রায়শই দুর্বল তৈলাক্তকরণ, দূষণ, ভুল সারিবদ্ধতা, বা ক্লান্তি। তাপ এবং টর্কের মতো চরম অবস্থা পরিধানের গতি বাড়ায়।

প্রশ্ন 4: সুই বিয়ারিং বল বিয়ারিং প্রতিস্থাপন করতে পারেন?

মাঝে মাঝে, হ্যাঁ, সংকীর্ণ জায়গায় উচ্চ লোড প্রয়োজন। কিন্তু বল বেয়ারিং উচ্চ নির্ভুলতা এবং কম টর্ক জন্য ভাল উপযুক্ত।

প্রশ্ন 5: কত ঘন ট্রান্সমিশন বেয়ারিং পরীক্ষা করা উচিত?

ব্যবহারের উপর নির্ভর করে, কিন্তু নিয়মিত তেল পরিবর্তন এবং কম্পন পরীক্ষা সাহায্য করে। প্রাথমিক লক্ষণ হিসেবে গোলমাল বা গরমের সন্ধান করুন।