Why Choose Needle Roller Bearings?

2026-01-30সুই রোলার বেয়ারিং stand out as one of the smallest and most effective options in rolling-element bearing designs. Their special long and narrow cylindrical rollers—usually with length-to-diameter ratios of 4:1 or more—offer outstanding radial load support in very tight radial areas. This mix of strong load handling, tiny size, and lower weight makes needle roller bearings a top pick for today’s machines. Space saving and solid performance under pressure really matter here.

সুই রোলার বিয়ারিং কি?

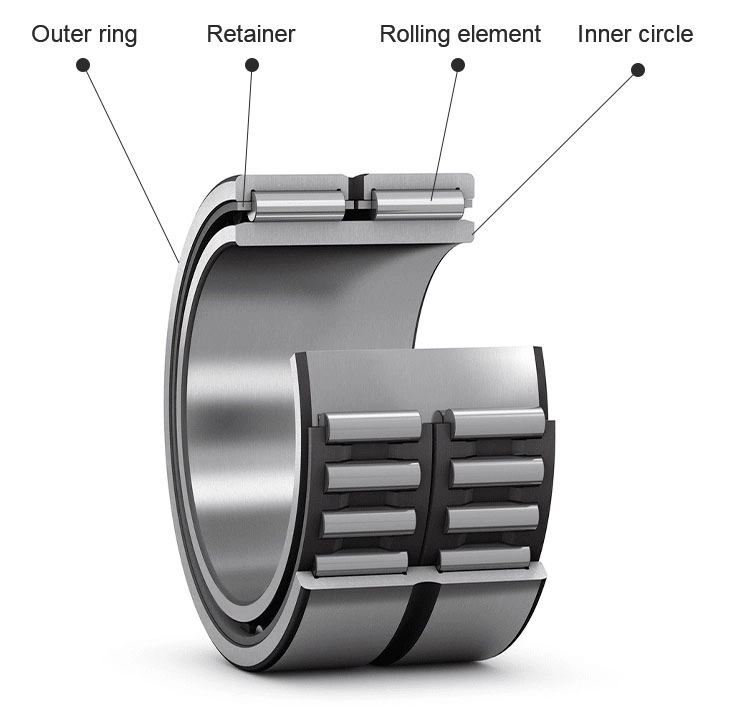

সুই রোলার বেয়ারিং use long, slim cylindrical rollers (often called needles). These rollers move between an inner and outer raceway or right on a shaft and housing. The setup spreads the load across a much bigger surface than ball bearings or regular cylindrical roller bearings do. As a result, they carry heavier loads in a really small radial space.

Key differences from other bearing types include:

-

Shape and Size — Needle rollers are far longer and slimmer than balls or standard cylindrical rollers. This lets them fit in narrow radial spaces.

-

লোড ক্যাপাসিটি — They provide very high radial load ratings for their cross-section size.

-

Friction and Efficiency — Rolling friction stays quite low, particularly in caged types. This helps power move smoothly and efficiently.

-

Cage Design — Caged styles keep rollers aligned and apart with accuracy. Full-complement styles pack in the most rollers possible for maximum load ability.

-

Alignment Sensitivity — They react more to shaft or housing misalignment than self-aligning or spherical bearings.

-

Typical Applications — Automotive transmissions, gearboxes, power tools, compressors, and aerospace parts where radial room stays limited.

Common Types of Needle Roller Bearings

Drawn Cup Needle Roller Bearings

These have a thin-walled outer cup formed by drawing. It acts as the outer race. The light build plus strong radial load ability makes drawn cup needle roller bearings perfect for automotive transmissions, small electric motors, and everyday industrial gear. Weight and cost play big roles in these cases.

Full-Complement Needle Roller Bearings

No cage exists here. These bearings fit the greatest number of rollers into the space available. More rolling parts create very high static and dynamic load ratings. Still, roller-to-roller touch raises friction a bit. Full-complement types work best in low- to medium-speed, heavy-load situations like tough gearboxes and hydraulic setups.

Caged Needle Roller Bearings

A careful cage keeps rollers separate and on track. It stops twisting and touching between nearby needles. This setup cuts friction and heat a lot. It allows faster spinning speeds and longer life in tough spots such as high-speed spindles and racing car parts.

Why Choose Needle Roller Bearings Over Other Bearings?

Space-Efficient Design for Tight Spaces

The very small radial section lets needle roller bearings squeeze into places where ball bearings or tapered roller bearings need much more room. In car transmissions, they hold gear shafts between parts that sit close together. In aerospace actuators and landing gear, they cut down the total size and weight of the system.

High Load-Carrying Capacity in Compact Form

The long line contact between needle rollers and raceways spreads loads over a bigger area. This beats the point contact of ball bearings and the shorter contact of regular cylindrical rollers. So, radial load ratings jump much higher for the same bearing diameter.

Needle Roller Bearings vs. Ball Bearings

-

Rolling Elements: Needle-shaped rollers vs. spherical balls

-

লোড ক্যাপাসিটি: High radial capacity for size vs. moderate radial capacity

-

Space Efficiency: Very compact radial section vs. larger radial requirement

-

ঘর্ষণ: Higher line contact friction vs. lower point contact friction

-

Speed Capability: Moderate to high (caged designs) vs. very high

-

Primary Applications: Compact, high-load machinery vs. high-speed, lighter-load equipment

Needle Roller Bearings vs. Cylindrical Roller Bearings

-

Rolling Elements: Long thin needles vs. shorter, larger-diameter cylinders

-

Size: Minimal radial section vs. larger radial section

-

লোড ক্যাপাসিটি: Very high for given radial space vs. high absolute capacity

-

Space Efficiency: Superior in confined radial envelopes vs. requires more radial room

-

Speed Capability: Moderate vs. higher

-

সাধারণ ব্যবহার: Space-critical applications vs. heavy industrial machinery

Lightweight, High-Strength Bearings for Reduced Weight Applications

They use little material and have a small shape. So needle roller bearings weigh far less than others with the same load ability. This weight drop matters a lot in aerospace turbine shafts, car drivetrains, and electric vehicle powertrains. Every gram affects efficiency, range, and overall results.

Performance Advantages of Needle Roller Bearings

Low Friction and High Efficiency

Well-shaped rollers, smooth surfaces, and good lubrication create low friction when everything lines up right. Less friction means lower energy use, cooler running, quieter work, and better system performance. This shows clearly in CVT systems and power tool gearboxes.

Durability and Longevity Under Heavy Loads

Made from through-hardened or case-hardened bearing steel, these bearings stand up to fatigue, wear, and shape changes during long heavy radial loads. Full-complement styles spread stress over more parts and boost lasting power even more.

High-Speed Capability in Caged Needle Bearings

Accurate cages guide rollers well at fast speeds. They prevent twisting and cut inside friction. Caged needle roller bearings run smoothly in CNC spindles over 30,000 rpm, Formula 1 gearbox idler gears, and aerospace accessory drives.

Specific Application Advantages of Needle Roller Bearings

Versatility Across Multiple Industries

-

Automotive: transmissions, constant-velocity joints, rocker arms, and steering systems

-

Aerospace: turbine engine shafts, flap actuators, landing gear assemblies

-

Heavy Machinery: excavator pivot points, crane sheaves, agricultural implement gearboxes

-

Manufacturing: high-speed spindles, conveyor rollers, textile machinery

-

Electric Motors & Drives: rotor support in compact EV and industrial motor designs

Superior Performance in Oscillating Motion Applications

The big contact area and low Hertzian stress help needle roller bearings perform well in back-and-forth or swinging motion. Examples include universal joints, piston pin bearings, and pump connecting rods. Other bearings often face sliding or fretting wear in these spots.

High Radial Load Capacity for Demanding Environments

Needle roller bearings manage huge radial loads in planetary gear sets, hydraulic pumps, wind turbine pitch and yaw drives, mining equipment pivots, and big industrial compressors. They stay very dependable.

Challenges and Considerations When Using Needle Roller Bearings

Sensitivity to Misalignment

Even tiny angle errors lead to edge pressure, faster wear, and possible brinelling. Good shaft and housing alignment plus correct mounting steps stay very important.

Solutions to Manage Limited Misalignment Tolerance

-

Self-aligning needle roller bearing variants

-

Flexible or elastomeric mounting arrangements

-

Regular alignment verification during maintenance

-

High-precision machining of mating components

-

Real-time vibration and temperature monitoring systems

Limited Axial Load Capacity

Needle roller bearings focus on radial loads. Pure axial loads or heavy combined forces can harm roller ends. Add thrust washers, thrust needle roller bearings, or extra axial supports when axial forces appear.

উপসংহার

Needle roller bearings deliver a great mix of high radial load ability, tiny radial size, light build, and steady work in many conditions. They keep giving long life in tight spaces with heavy loads. That makes them essential for automotive, aerospace, industrial, and renewable energy uses.

LQYS বিয়ারিং

LQYS বিয়ারিং specializes in manufacturing and supplying a full range of high-precision needle roller bearings—including drawn cup, full-complement, caged, and thrust designs—engineered to meet demanding industry specifications.

সাধারণ প্রশ্ন

What gives needle roller bearings their high load capacity in small spaces?

The long line contact between thin rollers and raceways spreads load across a wide area. It allows high radial ratings in a very small radial section.

In which applications do needle roller bearings outperform ball bearings?

They shine where high radial load meets limited space. Good examples are automotive transmissions, planetary gears, and small gearboxes.

Can needle roller bearings operate at very high speeds?

Caged designs handle fast rotation well. Full-complement types suit lower- to medium-speed, high-load jobs better.

How should misalignment be addressed when installing needle roller bearings?

Use accurate alignment tools, self-aligning versions if possible, flexible mounts, and regular vibration checks. These help spot and fix misalignment early.

Are needle roller bearings suitable for axial loads?

They mainly handle radial loads. Include dedicated thrust needle roller bearings or separate axial supports when big axial forces exist.

Partner with a Trusted Manufacturer and Seller

Industrial equipment manufacturers, automotive component producers, machinery OEMs, bearing distributors, and application engineers seeking consistent quality, competitive lead times, and application-specific needle roller bearing solutions benefit from collaborating with LQYS Bearings. As an experienced manufacturer and seller, LQYS Bearings delivers precision-engineered needle roller products backed by advanced production capabilities, rigorous quality control, and dedicated technical support. Reach out today via email at salesjake@lqysbearing.com, WhatsApp at +8618013237311, or telephone at +8613002187311 to discuss project requirements, request samples, obtain quotations, or explore custom bearing solutions tailored to exact performance needs.

পূর্ববর্তী: কিছুই না

পরবর্তী: 16-types-of-vehicle-bearings-used-in-automotive-applications