A Quick and Easy Guide to Spherical Roller Thrust Bearings

2025-12-18Spherical roller thrust bearings mark a key step forward in bearing tech. These parts handle big axial loads. They also deal with misalignment and sudden shocks. The design uses two rows of curved spherical rollers. These sit between curved washers. This setup allows self-alignment. It gives strong performance. In factories, where exact work and toughness matter under tough conditions, spherical roller thrust bearings shine. They cut friction. They boost work flow.

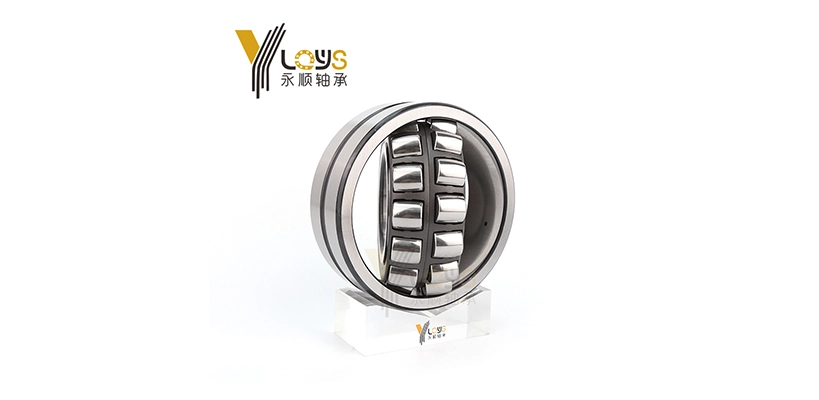

Definition of Spherical Roller Thrust Bearings

Spherical roller thrust bearings act as special parts. These support mostly axial loads in one way. They take some radial forces too. The main build has an inner ring with a flat path. An outer ring holds a curved path. Barrel-shaped rollers fit inside. These allow smooth turn even with angle shifts. This setup lets the bearing fix shaft bend or housing tilt up to a few degrees. This trait helps in changing settings.

Made with exact ground faces, these bearings use cages. Cages often come from stainless steel or brass. These guide rollers. They keep even gaps. This cuts inner stress. Hard washers add strength. They spread loads well. The whole unit gives low start twist. It fights wear out. Good for medium speed work, spherical roller thrust bearings fit spots that need big thrust power. They avoid too much heat. This sets them apart from cylindrical or tapered types. Those lack built-in self-alignment.

Features and Benefits of Spherical Roller Thrust Bearings

High Load-Carrying Capacity

Spherical roller thrust bearings gain top axial load help from better roller shape and inner shape. They manage forces many times bigger than radial ones. The even roller layout spreads force smoothly over paths. This stops local damage even under max loads at slow turns. This strength fits tough fields like ship drive and big factory presses. Stability under changing thrust matters most.

Extra stiffness in axial, radial, and tilt ways adds to work. It keeps steady run amid shifting states. By handling these load types, the bearings give long trust. They lower sudden break risk. They make gear last longer.

Accommodate Misalignment

The built-in self-fix system of spherical roller thrust bearings comes from curved roller shapes. These match the curved outer path. They adjust to angle changes without losing load power. This trait helps in spots with shakes or heat growth, like turning machines under uneven loads.

These bearings work both ways. They fight hits and wear. They keep exact in uneven load spreads along the shaft. Their flex cuts setup limits. It makes putting together easier in hard housings. It boosts whole system strength.

Separable Design

A key mark of spherical roller thrust bearings is their split build. It has separate inner rings, roller groups with cages, and outer washers. These come apart without touching nearby parts. This easy split speeds up putting in and taking out. It saves time and work in repair plans.

In tight spots or update work, the design gives room to move. It allows exact placement. It keeps alignment. As a result, work trust grows. Wear on matching parts drops. Motion range widens for big setups.

High-Speed Capability

Built with low-rub paths and smooth roller ways, spherical roller thrust bearings back fast speeds. They cut heat rise and power loss. The curved shape lowers slide touch. It helps fluid lube. This keeps work good during speed up or slow down.

Shock take stays strong. This makes these bearings fit for quick high-speed needs in turbines or movers. Toughness under repeat stress is a must.

Long Service Life

Toughness marks spherical roller thrust bearings. It comes from small shapes with little radial space. Built-in cages cut rub damage. Face treats fight rust in wet or chemical air. Better stress shapes slow wear start.

Regular lube with grease or oil, plus checks, stretch time between fixes. This brings cost savings in non-stop work fields.

Low Friction

Rub cut in spherical roller thrust bearings comes from smooth faces and exact roller match. This leads to cooler run and less shake. This help backs higher output in load-heavy rounds. Setups fit exact twist needs.

Side-by-side looks show less power use than old thrust types. This highlights their part in green making.

Applications of Spherical Roller Thrust Bearings

Blowout Preventers

In oil and gas pull, blowout preventers use spherical roller thrust bearings to control fluid under huge pressure. They reduce valve and seal wear. Their hit strength keeps work amid strong shakes. This lengthens system run. It cuts work costs.

Classifiers

Material sort gear, like shake screens, gain from the bearings’ way turn and align fix. This helps exact particle split. Strength under big feeds boosts output. Self-center traits fight setting changes.

Extruders

Extrusion steps in plastics and metals push axial thrusts from twist. Spherical roller thrust bearings cut shaft wear. They keep twist true. Low-rub run raises exact. This matters for even product push.

Gearboxes

Gearbox units in big rides and machines add these bearings for both-way axial control. They damp shakes during gear change. Easy repair and heat strength back long work in hot spots.

Metal Millwork/Backup Rolls

Rolling mills for metals use spherical roller thrust bearings to fight bend in backup rolls. They take tilt moments and dirt. Strong cages guard insides. This ensures steady strip quality in dusty mills.

Pre-Heater Fans

Factory fans in preheaters face repeat loads from blade uneven. The bearings’ hit take and speed flex keep air flow good. Less noise and heat fit strict work rules.

Pumps

Centrifugal and positive-displacement pumps use the bearings’ even pressure spread for axial-radial balance. They push heat away well to stop overheat. Align fix guards moving seals. This boosts pump life.

Screw Conveyors

Bulk move via screw conveyors sends changing thrusts from material rush. The bearings’ high hit power and small shape handle this. Rub cut smooths move. It betters energy use in shipping.

Design and Construction of Spherical Roller Thrust Bearings

Basic Components of a Spherical Roller Thrust Bearing

The unit has curved paths centered on the bearing axis. Two roller rows link inner and outer parts. Load paths mix axial and radial ways. Self-align cuts bend errors. Lube paths keep high-speed strength. Stiffness beats usual types. It fits turbines, compressors, and motors.

Types of Spherical Roller Thrust Bearings

Cylindrical bore kinds fit straight shafts with wide touch for heavy tasks. Tapered bores allow direct shaft fix without extras. They shine in axial-radial mix. Split designs speed service by parting outer races. Good for load-change or misaligned shafts.

Materials Used for Spherical Roller Thrust Bearings

Chrome steel leads for its pull strength and hit last. Paired with wear-fight roller mixes. Better lubes and coats strengthen against scrape and rust. Custom sizes for special needs.

Cage Design and Variations

Cages, cut from brass or polyamide, direct roller spread for speed boost and load even. Changes fit shake or axial-heavy shapes. They better align in turbine setups.

Conclusion

Spherical roller thrust bearings stand as key tools for axial-main uses. They mix high power, align take, and long life in small forms. Their low-rub, hit-strong shapes beat others in trust. They foster work flow across fields.

FAQ

What distinguishes spherical roller thrust bearings from other thrust types?

These bearings uniquely self-align via spherical rollers. They handle misalignment better than cylindrical variants. They support heavier axial loads.

In which environments do spherical roller thrust bearings perform best?

They excel in high-shock, moderate-speed settings like mining and marine operations. Vibration and thrust lead there.

How often should spherical roller thrust bearings be lubricated?

Intervals vary by load and speed. Typically every 1,000-2,000 hours. Checks for dirt guide changes.

Can spherical roller thrust bearings operate at high temperatures?

Yes, up to 200°C with right grease. Seals and cages affect limits.

What maintenance reduces failure in these bearings?

Regular align checks, proper lube, and dirt block stretch service life much.

Partner with LQYS Bearings as Your Trusted Manufacturer and Seller

LQYS Bearings, operating under Shanghai Yongheshun Import and Export Co., Ltd., stands as a top manufacturer and seller of high-precision spherical roller thrust bearings. It joins advanced make lines with strict tests for top quality. Serving clients in mechanical engineering, mining, steel, automotive, and railway sectors, LQYS Bearings gives custom fixes. These boost machine trust. They cut stop time. As a full-chain provider with world export reach, LQYS Bearings ensures fair pricing, fast send, and tech help fit to factory needs. Manufacturers and sellers seeking superior spherical roller thrust bearings for OEM integration or resale are invited to contact LQYS Bearings today at Email :salesjake@lqysbearing.com

or Whatsapp :+8618013237311,Tel :+8613002187311 for catalogs and inquiries—lift your supply chain with proven excellence.