Comprehensive Guide to Angular Contact Ball Bearings

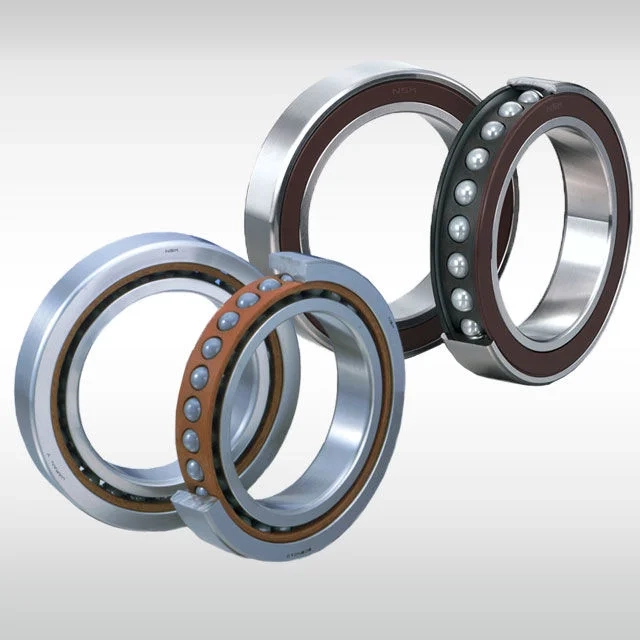

2026-01-08Explore the detailed world of Angular Contact Ball Bearings with this full guide. It looks at their design, how they work, and their strong points. These key mechanical parts handle both radial and axial loads together well. They support fast spinning speeds and allow exact shaft placement in machines that rotate. Engineers and technicians count on Angular Contact Ball Bearings for better efficiency and top results in tough uses.

This guide reviews the various kinds of Angular Contact Ball Bearings. It includes single-row, double-row, and four-point contact versions. Each type gives special benefits that fit certain needs. The guide also explains correct installation, regular care, lubrication ways, and the many fields where these bearings are very important. Examples range from machine tools and robotics to cars and high-accuracy gear.

Understanding Angular Contact Ball Bearings

Angular Contact Ball Bearings are rolling element bearings built to take radial and axial loads at the same time. They work well in situations that need fast rotation and precise shaft control.

Main parts include inner and outer rings, balls, and cages. Designs come in single-row, double-row, and four-point contact styles. Materials often use high-grade steel, ceramic, or hybrid choices. These give strong lasting power, less drag, and longer life under hard conditions.

Cage structure and ball setup affect performance a lot. Well-made cages keep ideal ball gaps and straightness. They cut down friction and spread load evenly at high speeds. Ball setups make contact angles as large as possible. This boosts the bearing’s ability to handle mixed loads and lowers wear.

One main trait is the contact angle. It usually falls between 15° and 40°. This angle lets the bearing carry big axial loads in one direction plus radial support. Such a setup makes Angular Contact Ball Bearings very necessary for uses that need steady work in changing settings.

Angular Contact Ball Bearings offer clear benefits compared to other bearing kinds. They carry more combined radial and axial forces. This allows smaller setups and often removes the need for extra bearings. Lower drag helps reach faster running speeds. Precise build gives steady results. So these bearings fit high-efficiency systems well.

Types of Angular Contact Ball Bearings

Many kinds of Angular Contact Ball Bearings exist. Each has special builds to meet different load, speed, and space needs. The main groups are single-row, double-row, and four-point contact bearings.

Single Row Angular Contact Ball Bearings

Single Row Angular Contact Ball Bearings have one row of balls. They manage combined radial and axial loads. Axial strength is mostly in one direction. Their small size fits uses with medium axial loads. They give high accuracy, low friction, and fast speed ability. These bearings help spread load well and stay dependable in setups that need exact control.

Double Row Angular Contact Ball Bearings

Double Row Angular Contact Ball Bearings use two rows of balls. They provide stronger stiffness and greater axial load ability in both directions. This setup gives even radial and axial backing. It suits heavy-duty cases that need stability and moment resistance. Double-row styles shine in uses that call for tough work and long life.

Four-Point Contact Bearings

Four-Point Contact Bearings feature special raceway shapes. These allow contact at four spots. They handle axial loads in both directions along with radial loads. This flexibility allows small designs without extra bearings for opposite axial forces. Four-point contact bearings keep smooth running under tricky loads. They offer dependability in tight spaces and high-performance settings.

Proper Installation and Maintenance

Good setup and steady care decide how well Angular Contact Ball Bearings perform and how long they last. Installation needs exact alignment. This avoids stress from misalignment, uneven load, or early breakdown. Correct fit on shafts and in housings matters. Controlled preload, when needed, boosts load ability and running efficiency.

Lubrication is very important. It cuts friction, spreads heat, and stops dirt. Common ways include:

-

Grease lubrication: Easy, low-cost, and good for sealed use in medium-speed cases over long periods.

-

Oil lubrication: Best for fast speeds because it gives less drag, better heat removal, and stronger cooling.

-

Solid lubricants: Used in harsh settings where normal types do not work. They give steady results at high heat or in vacuum.

Pick the right lubrication based on speed, temperature, and load. This reduces wear and lengthens service time.

Regular care includes cleaning off dirt, adding lubricant again when required, and checking for signs of wear. These signs can be strange noise, shaking, or rising heat. Quick replacement stops machine stops and keeps equipment dependable.

Applications of Angular Contact Ball Bearings

Angular Contact Ball Bearings work in many industries. They fit where mixed loads, fast speeds, and accuracy count. Usual uses cover machine tools, robotics, automotive systems, high-precision machinery, and similar areas.

In machine tools, these bearings hold spindle parts. They manage fast rotation and strong cutting forces. They keep exact placement in precision grinding machines and other gear that needs smooth, no-vibration work.

Robotics and automation gain from the bearings’ stiffness and load control. This allows accurate moves in jointed arms and fast systems.

High-precision machinery, like measuring tools and special devices, depends on these bearings. They give low backlash and steady work.

Other uses reach automotive parts. There they handle changing loads in transmissions and spinning groups. They also fit other industrial areas that need strength under mixed stresses.

Angular Contact Ball Bearings bring outstanding load ability, running efficiency, and flexibility. From single-row to four-point contact styles, each type solves certain engineering problems with custom features. Following good installation, lubrication, and care habits improves long life and dependability in all uses.

LQYS Bearings

LQYS Bearings, as a high-quality bearing manufacturer and seller, specializes in producing and supplying precision angular contact ball bearings, including single-row, double-row, and four-point contact types. With advanced production equipment, modern testing facilities, and a focus on high-precision solutions, LQYS Bearings supports industries such as machine tools, robotics, automotive, and high-precision machinery. Exporting to over 30 countries, the company integrates manufacturing, sales, and trade to deliver reliable products for demanding applications.

FAQ

What is the primary function of Angular Contact Ball Bearings?

Angular Contact Ball Bearings support combined radial and axial loads, with the contact angle enabling higher axial capacity in one direction while maintaining radial support.

What are the main types of Angular Contact Ball Bearings?

The main types include single-row (for moderate axial loads), double-row (for enhanced rigidity and bidirectional axial support), and four-point contact (for bidirectional axial loads in compact designs).

How does contact angle affect performance?

Higher contact angles (e.g., 30°–40°) increase axial load capacity, while lower angles (e.g., 15°–25°) favor higher speeds and radial emphasis.

What lubrication methods suit Angular Contact Ball Bearings?

Grease suits general and sealed applications, oil supports high speeds and heat dissipation, and solid lubricants handle extreme conditions.

In which industries are Angular Contact Ball Bearings most commonly used?

They appear frequently in machine tools, robotics, high-precision machinery, automotive systems, and other sectors requiring speed and accuracy.

Partner with a Reliable Manufacturer and Seller

Manufacturers and sellers seeking high-precision angular contact ball bearings benefit from partnering with an experienced supplier offering consistent quality and customization. LQYS Bearings provides a comprehensive range of angular contact ball bearings engineered for superior performance in demanding applications.

Contact the team today to discuss requirements, request quotes, or explore product specifications. Reach out via email at salesjake@lqysbearing.com, phone/WhatsApp at +8613002187311 / +8618013237311, or visit https://www.lqysbearings.com/ to discover solutions tailored to industrial needs. Secure reliable bearing supply for optimized machinery performance.