Improving Robotic Arm Linear Motion with Cam Follower Bearings

2025-10-27

Introduction to Linear Motion in Robotic Arms

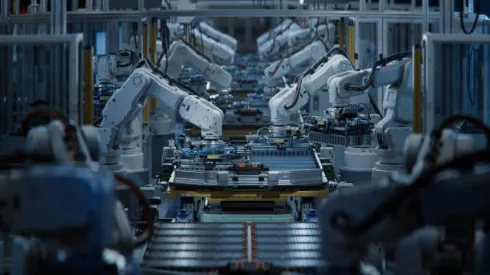

Robotic arms are key to today’s automation. They build cars, sort packages, and help in surgeries. Straight line movement, or linear motion, is vital for their work. Without smooth and accurate motion, things slow down, and mistakes happen. Cam follower bearings make this motion better.

Why Linear Motion Matters in Modern Robotics

Linear motion is the base for many robotic jobs. Smooth motion means faster work and fewer errors, which is critical in busy places like factories or hospitals. But it’s tricky. Friction can drag things down. Vibrations wear out parts. Misalignment messes up accuracy. These problems cause delays and pricey fixes. Cam follower bearings cut friction and keep motion steady.

Key Components in Linear Motion Systems

Linear motion systems need parts that work together. Linear guides set the path. Actuators give the push. Bearings make movement smooth. Bearings are the quiet stars here. They lower friction, carry heavy weights, and keep things lined up. Cam follower bearings shine because they’re made for specific tasks, like guiding a robotic arm on an exact route. Unlike regular bearings, they handle unique forces, which makes them great for automation.

What Are Cam Follower Bearings?

Definition and Structure

Cam follower bearings are special parts that follow a track or cam. They help create smooth linear or spinning motion. They usually have a stud or yoke, a roller, and an outer race. The roller slides along a surface, cutting down friction and wear. Compared to regular roller or ball bearings, cam followers are stronger. They’re built to carry heavy loads and follow odd paths. Their small size fits well in tight spots in robotic arms.

Common Types of Cam Followers

Cam followers come in different types. Stud type cam followers have a threaded stud for quick setup, great for small systems. Yoke type followers have a thicker inner race to handle bigger loads. They’re common in larger robotic setups. Special designs, like those with crowned rollers, ease edge stress and improve alignment. Picking the right one depends on the arm’s load, speed, and setup needs. For instance, a fast pick and place robot might use a stud type follower for easy mounting and dependability.

The Role of Cam Follower Bearings in Robotic Arm Motion

Reducing Friction and Vibration

Friction slows things down. It wears out robotic arm parts. Cam follower bearings fix this by using rollers to lower resistance. They also reduce shaking, which matters in fast tasks. Less shaking means less wear on joints and slides. This makes the arm last longer. One factory saw a 30% drop in repair costs after using cam followers in their assembly robots.

Enhancing Precision and Stability

Accuracy is huge in robotics. A robotic arm welding car parts needs to be spot-on, down to a millimeter. Cam followers keep things steady by staying aligned, even with fast speeds or heavy loads. Their solid build stops wobbling. This keeps motion predictable. It’s super important in tasks like 3D printing or CNC cutting, where precision is everything.

Supporting Heavy Loads and Repetitive Motion

Robotic arms often lift heavy stuff or repeat moves thousands of times a day. Cam followers are made for this. They have high load strength and tough materials. They’re perfect for joints and linear slides. They handle the stress of repeated tasks without breaking or bending. That’s why they’re a top pick for industrial automation.

Benefits of Using Cam Follower Bearings in Linear Motion Systems

Longer Service Life and Reliability

Cam followers are sturdy. They handle big loads and resist damage, so they last longer than regular bearings in tough settings. This dependability cuts downtime, a real pain for factories. Some cam followers can run for up to 50,000 hours before needing a swap, depending on the job.

Easy Maintenance and Replacement

Robotic arms often work in tight spaces. There’s no room for big parts. Cam followers are small, so they’re easy to install and replace. Their design makes lubrication simple, which saves time on upkeep. A quick change can get a production line running again in minutes, not hours.

Improved Performance in Harsh Environments

Factories can be rough—dusty, wet, or super hot or cold. Regular bearings might fail in these conditions. Cam followers, especially sealed ones, keep going strong. They work in dusty warehouses or humid cleanrooms. This toughness makes them a go-to for robotics in hard places.

The Bearing Expert You Need

Precision Manufacturing and Quality Control

Yongheshun, a top bearing maker, crafts cam followers with tight quality checks. Their factories use high tech tools and tests to ensure every bearing meets industry standards. This care ensures reliability in robotic tasks, where accuracy is key.

Custom Solutions for Robotic Applications

Not all robotic arms are alike. Yongheshun offers custom cam follower designs to fit specific automation needs. Got a unique load or mounting setup? Their engineers can help. This flexibility is a big deal for companies building special robots.

Global Supply and Technical Support

Yongheshun delivers bearings worldwide and offers great support. Their team helps clients pick the right bearings and solve problems. This service keeps robotic systems running, no matter where they are.

Yongheshun vs. Timken and SKF

Yongheshun’s cam followers match big names like Timken and SKF in quality. Their focus on smart production and supply means faster delivery, a win for factories with tight schedules. But quality stays high—Yongheshun’s bearings are built to last.

Choosing the Right Cam Follower for Your Robotic Arm

Key Selection Criteria

Picking a cam follower isn’t one size fits all. Load capacity is a big deal—can it handle the arm’s weight? Speed is another factor; fast jobs need low friction designs. Lubrication and mounting matter too. Sealed cam followers work well in dusty spots. Stud type ones are great for quick setups.

Conclusion

Cam follower bearings boost robotic arm linear motion. They cut friction, improve accuracy, and handle heavy loads with ease. Their strength and flexibility make them perfect for automation, from factories to operating rooms. For companies aiming to improve their robotic systems, these bearings are a smart pick. Reach out to Yongheshun for product details or expert tips on finding the best cam follower for your project.

FAQ

Q1: What makes cam follower bearings different from standard bearings?

Cam followers follow a track or cam. They handle unique loads and paths. They’re stronger than regular roller or ball bearings, which suits robotic arms.

Q2: Can cam followers handle high speed robotic applications?

Yep, many are made for fast jobs. Their low friction design and solid build keep things smooth, even at high speeds.

Q3: How often do cam follower bearings need maintenance?

It depends on the job. Their small size and easy lubrication make upkeep simple. Sealed ones last longer, especially in tough spots.

Q4: Why choose Yongheshun for cam follower bearings?

Yongheshun offers top quality bearings, custom options, and global support. Their products rival big brands and often arrive faster.

Q5: Are cam followers suitable for small robotic arms?

For sure. Their small size and easy setup make them great for tiny, space tight robotic systems.