Industrial Solutions: How to Choose Self-aligning Bearings

2026-01-22Self-aligning Bearings Features

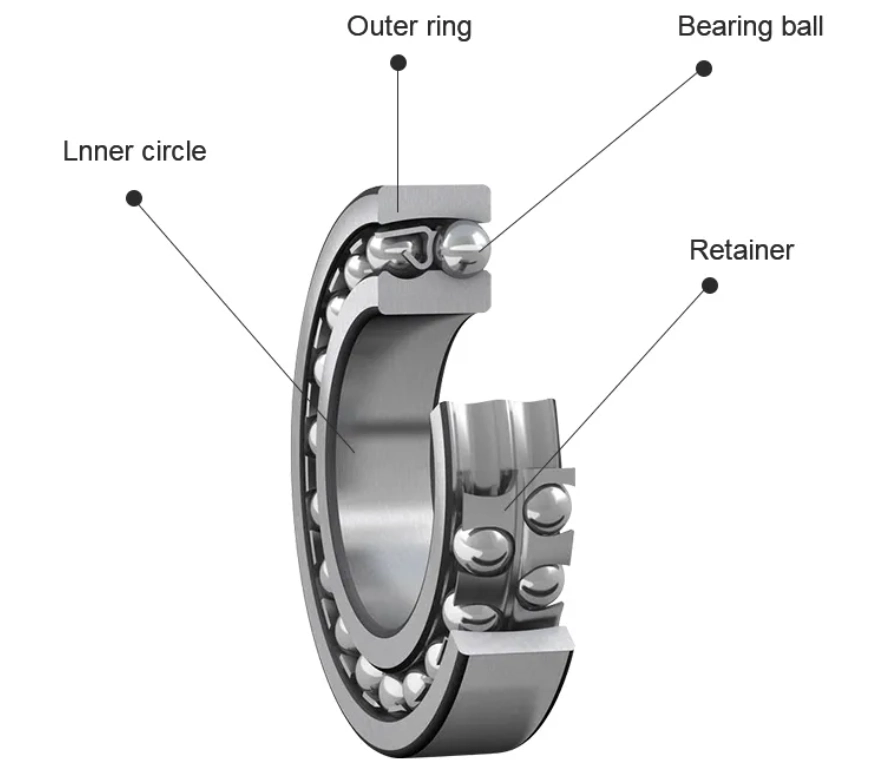

Self-aligning ball bearings have a double-row ball setup. They come with a spherical outer raceway and two deep groove raceways on the inner ring. You can find them in open style or sealed style.

The round shape of the outer raceway lets these bearings handle quite a bit of misalignment between shaft and housing. They easily correct angular mistakes from shaft bending or poor mounting.

Main features include:

-

Handles both static and dynamic alignment mistakes Just like spherical roller bearings or CARB toroidal roller bearings, self-aligning ball bearings show very good self-aligning ability. They can correct misalignment up to about ±3 degrees in most cases.

-

Really good at high speeds These bearings create much less friction than many other rolling bearing kinds. Because of this, they stay cooler during fast operation.

-

Needs very little maintenance Lower heat means longer life and longer gaps between service times. This makes them perfect for machines that must run reliably for a long time.

-

Very low friction The design leaves bigger space between the balls and the outer ring. This greatly cuts down friction and heat.

-

Works very well with light loads Self-aligning ball bearings need only a small minimum load. They run smoothly under light loads without any skidding problems.

-

Very quiet operation In things like fans, these bearings lower both noise and vibration. This gives smoother and more quiet working.

Types of Self-aligning Bearings

Self-aligning ball bearings exist in several versions to match different needs:

Open Self-aligning Bearings

-

With cylindrical bore

-

Bearings with locking devices on an adapter sleeve

-

With tapered bore, e.g., used with an adapter sleeve

-

With extended inner ring

Sealed Self-aligning Bearings

-

With cylindrical bore

-

With tapered bore, e.g., used with an adapter sleeve

Sealed types give good protection against dirt. However, they usually allow a little less angular misalignment than open types.

Large Self-aligning Bearings

These have an annular lubrication groove on the outer ring. They also feature three equally spaced lubrication holes on the outer ring and six on the inner ring. They work well in situations that need both low friction and high load capacity, such as in the paper industry.

Bearings with extended inner ring

These are made for regular commercial shafting in easier applications. They allow simpler mounting on normal shafts.

Installing Self-aligning Bearings

Correct installation helps the bearings last longer and work better.

Installing cylindrical bore bearings

-

Separable bearings The inner ring and outer ring can go in separately. This makes things easier, especially when both need tight fits. When you slide the shaft with inner ring into a housing that already has the outer ring, take care to line things up properly. This prevents harm to raceways and balls. A guide sleeve is helpful for cylindrical or needle bearings when the inner ring has an edge on one side or no edge.

-

Non-separable bearings Put the ring that needs the tight fit in first.

-

Cold mounting For small bearings with normal fits, you can gently tap them into place using a hammer and an installation tool. Apply force right in the center. When mounting both rings at once, press evenly on inner and outer rings. Make sure the tool touches both rings in the same plane. Special bearing mounting tools are better when you have them.

Installing tapered bore bearings

Self-aligning ball bearings that have tapered bores use these fitting methods:

-

Feel the clearance drop by turning and tilting the outer ring (good for bearings with normal radial clearance, not sealed ones). The outer ring spins freely but feels a small drag when tilted side to side. This shows the clearance is correct.

-

Check the locking angle on the locknut.

-

Measure the axial movement distance.

These simple checks help get a precise fit and good alignment for steady performance.

Self-aligning ball bearings offer a smart and affordable answer in industries that face misalignment problems. Their automatic correction of shaft misalignment removes alignment headaches. It also cuts installation expenses, stops early damage from edge pressure, and brings down total maintenance costs. The structure keeps stable performance even when shafts bend or housings change shape. Therefore, they suit applications with long shafts, heavy loads, or tricky mounting setups very well.

Common industries include mechanical equipment, automotive, engineering, railway, steel, electricity, textile, metallurgy, mining, oil, papermaking, and more. The bearings manage moderate radial and axial loads. At the same time, they perform especially well in high-speed situations with low friction.

When choosing self-aligning ball bearings, look at load type, speed, amount of misalignment, working environment, and whether sealing is needed. Open styles fit cleaner places and accept more misalignment. Sealed versions give better protection in dirty conditions.

FAQ

What are the main advantages of self-aligning ball bearings over other bearing types?

Self-aligning ball bearings do very well at handling misalignment. They give low friction for fast applications, need almost no maintenance, and work nicely under light loads with less noise and vibration.

What is the typical angular misalignment capacity for self-aligning ball bearings?

These bearings generally handle angular misalignment up to ±3 degrees. The exact amount depends on the design and load situation.

Are sealed self-aligning ball bearings suitable for high-misalignment applications?

Sealed versions protect against dirt well. Still, they usually allow a bit less angular misalignment than open designs.

How do self-aligning ball bearings contribute to cost savings?

They make service life longer, reduce how often maintenance is needed, prevent early wear from misalignment, and lower the total cost of ownership through dependable performance.

What applications benefit most from self-aligning ball bearings?

Applications that have possible shaft bending, hard alignment, or long shafts benefit most. Examples include fans, conveyors, agricultural machinery, woodworking equipment, and industrial machines in mining, papermaking, and automotive areas.

Partner with a Reliable Manufacturer and Seller for Your Bearing Needs

Clients in the industrial sector seeking high-quality self-aligning ball bearings benefit from partnering with established suppliers offering integrated production, precise engineering, and comprehensive support. LQYS Bearings, as a high-quality bearing manufacturer, importer, and exporter in China, integrates production, sales, trade, and export to deliver high-precision bearings. With advanced production equipment, modern testing processes, and a wide range of products including self-aligning ball bearings, the company serves diverse industries with reliable solutions.

Contact LQYS Bearings today for expert consultation, product catalogs, or customized bearing solutions:

WhatsApp: +8618013237311

Tel: +8613002187311

Email: salesjake@lqysbearing.com

Elevate production efficiency with proven bearing expertise. Reach out now to discuss requirements and secure optimal bearing performance.