Unraveling the Precision: A Comprehensive Guide to Linear Bearings and Their Functionality

2026-01-09Linear bearings act as key parts in today’s machines and mechanical setups. They allow smooth and exact straight-line movement with very little friction. These parts turn spinning motion into steady straight travel. They bring good efficiency, clear accuracy, and long life in many different uses. This guide looks at the kinds, basic ways they work, main parts, how they fit with shafting, how they differ from normal bearings, and their wide range of uses.

Understanding Linear Bearings

Linear bearings help control motion in a straight line. They cut down extra friction and wear. Careful design makes sure they work well in setups that need exact placement and the same results every time. Many fields count on these bearings for tools like CNC machines, factory robots, linear actuators, and automatic assembly lines.

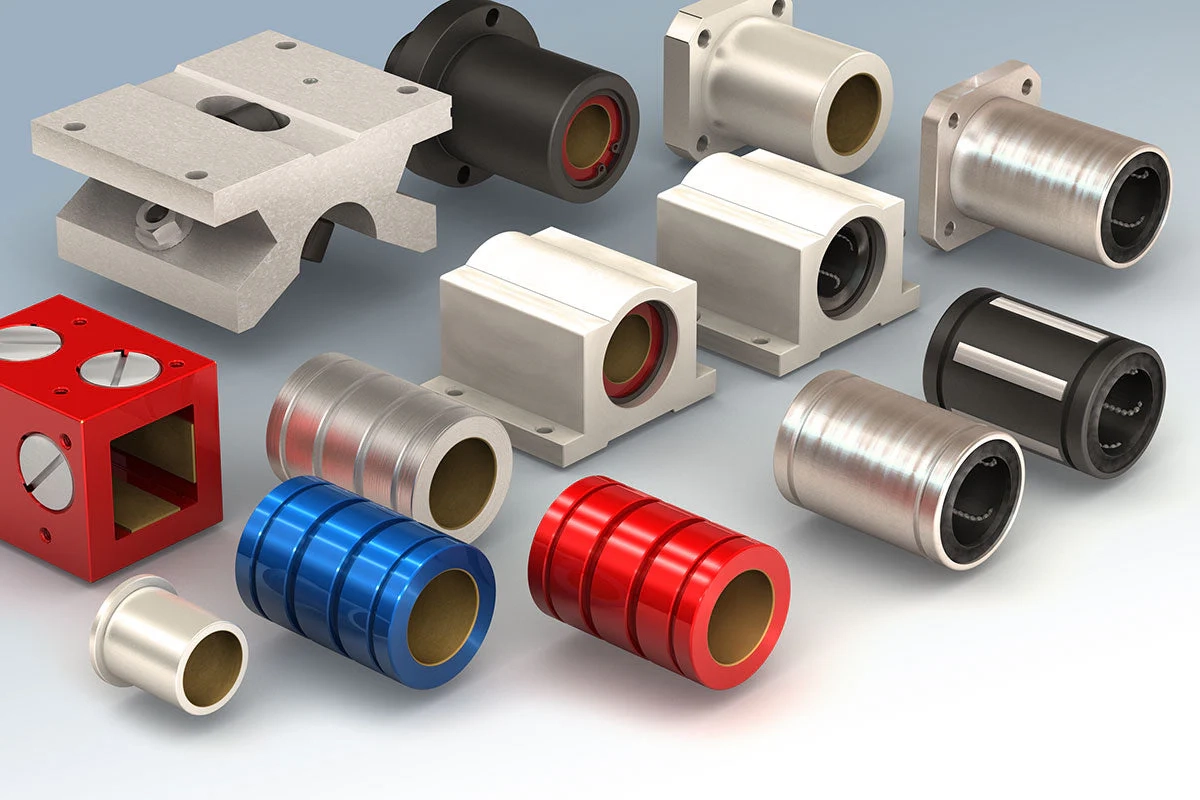

Types of Linear Bearings

Ball Bearings

Ball bearings use balls that move around to lower friction between parts that shift. Types like deep groove and angular contact give strong accuracy and easy motion. They work best in cases that need little backlash and fast running.

Roller Bearings

Roller bearings use round rollers to hold bigger weights with even spread. Kinds such as cylindrical and needle roller bearings do well in tough jobs where strong load support and steady balance are important.

Linear Bushings

Linear bushings, sometimes called linear ball bearings, have a round outer case and an inside holder for balls. This setup gives low friction, good accuracy, and almost no backlash. It fits well in tight spaces or spots that demand high precision.

Linear Slide Systems

Linear slide systems put together rails, carriages, and rolling pieces for guided straight movement. These complete units lead in automation, machine tools, and places that need high repeat accuracy.

How Linear Bearings Function

The main idea is to cut friction by using rolling parts instead of sliding touch.

Ball Bearings

Turning races push balls to roll. This lets smooth straight shifts with less push-back.

Roller Bearings

Round rollers spread loads in an even way. They avoid direct touch on surfaces and improve how well things run.

Linear Bushings

Balls move in loops inside holders between the case and shaft. They give exact and steady motion.

Linear Slide Systems

Rails and carriages use balls or rollers. This provides smooth and repeatable direction under different weights.

Linear bearings support steady motion in modern engineering. New improvements keep making their part bigger in automation and exact tech.

Components that Work Together

Good linear motion setups bring several parts together for smooth work. Common ones include:

-

Linear Rails or Guides — Give steady paths for bearing movement and keep things lined up.

-

Carriages — Hold bearings in place, spread loads, and connect to moving parts.

-

Drive Mechanisms — Belts, lead screws, or ball screws change spinning force to straight force.

-

Linear Motors — Give direct straight push in some fast or low-care uses.

-

Support Structures — Frames and brackets make sure the base stays firm and holds loads.

-

End Supports — Fix rail ends to stop any shift out of line or side move.

-

Encoders and Sensors — Provide data on position, speed, and exactness for closed-loop control.

-

Bearing Housing or Blocks — Protect and fix bearings to make them last longer.

-

Seals and Lubrication — Keep out dirt and keep friction low.

-

Mounting Hardware — Bolts and fasteners hold the whole setup tight.

-

Controllers and Electronics — Handle motion orders in automatic systems.

-

Power Supply — Powers motors, drives, and controls.

These parts join to create strong and trusty linear systems made for certain needs.

Shafting

Shafting makes the main track for linear bearings. It offers ground surfaces with high accuracy for low-friction guidance. Main benefits include:

-

Support and Guidance — Accurate shafts keep bearing alignment and system balance.

-

Load Distribution — Even spread of force stops stress build-up.

-

Alignment Accuracy — Smooth and steady surfaces make sure motion stays on track with no drift.

-

Material Selection — Hardened steel, stainless steel, or alloys mix strength, rust protection, and long life.

-

Surface Finish — Polished or chrome-plated surfaces cut friction and wear.

-

Corrosion Resistance — Special materials stand up to rough settings.

-

Length and Dimensional Accuracy — Exact sizes fit the needed travel lengths.

-

Integration — Shafts line up with bearings, housings, and supports for full teamwork.

Accurate shafting makes linear bearings work their best. It keeps things reliable in industry.

What Makes Linear Bearings Different?

Linear bearings stand apart from regular rotary bearings in build and goal, even though both cut friction.

Direction of Motion

Linear bearings allow straight travel without any turn. Regular bearings handle spinning motion.

Construction

Linear types use rails, carriages, looping balls, or rollers for straight guidance. This differs from the simpler build of rotary ones.

Applications

Linear bearings fit CNC tools, robotics, and actuators. Regular bearings go with motors, wheels, and turning shafts.

Load Handling

Linear bearings deal with loads along the motion line. Regular bearings take radial and axial forces during spin.

Design Complexity

Linear bearings have special guides and setups for accuracy. Regular bearings give wider options for rotary uses.

These differences make linear bearings a focused choice for straight-line accuracy.

Applications

Linear bearings give exact motion in many areas:

-

CNC Machines — Allow correct tool placement.

-

Industrial Robotics — Help control joints and actuators for pick-and-place work.

-

Linear Actuators — Change motion in cars, medical tools, and automation.

-

Automated Manufacturing Systems — Run conveyors, part handling, and assembly.

-

Medical Equipment — Give controlled moves in imaging and surgery devices.

-

Packaging Machinery — Help with filling, sealing, and labeling precision.

-

Aerospace Systems — Support landing gear, controls, and moving parts.

-

Semiconductor Manufacturing — Handle wafers and give exact placement.

-

Automotive Applications — Improve steering, throttle, and suspension work.

-

Textile Machinery — Manage weaving and fabric steps.

-

Rail and Transportation Systems — Run doors and seat moves.

-

Mining Equipment — Back conveyors and drilling in hard places.

These examples show how flexible linear bearings are in pushing factory efficiency.

Linear bearings stay important in many fields. They drive progress in automation, accuracy, and dependability. Their growth keeps shaping engineering work.

LQYS Bearings

LQYS Bearings stands as a trusted manufacturer and seller of high-precision bearings, including linear bearings designed for smooth, low-friction motion with recirculating ball systems, high rigidity, and compatibility with various rails. With advanced production facilities and a focus on quality, LQYS Bearings delivers solutions for automation, CNC, and industrial needs worldwide.

Frequently Asked Questions (FAQ)

What are the primary advantages of linear bearings over sliding mechanisms?

Linear bearings give much lower friction, better accuracy, longer life, and less upkeep thanks to rolling parts and smart designs.

How do linear bushings differ from linear slide systems?

Linear bushings center on small, shaft-based motion with ball loops. Linear slide systems mix rails and carriages for wider load hold and easy changes.

What shaft materials suit linear bearing applications?

Hardened steel brings toughness. Stainless steel gives rust protection. Special alloys handle environment or load needs.

In which industries do linear bearings see the most use?

Main areas cover automation, CNC machining, robotics, medical devices, semiconductor production, packaging, and aerospace.

Can linear bearings handle heavy loads?

Yes. Roller types and strong designs take big loads. Proper size and match with good shafts and guides make it work.

Partner with a Reliable Manufacturer and Seller for Linear Bearing Solutions

Manufacturers and sellers looking for steady supply of high-precision linear bearings, shafting, and related parts gain from working with a solid provider. LQYS Bearings, as a dedicated manufacturer and seller, offers OEM-quality products, customization options, and global export support. Contact the team today for technical specifications, quotations, or application guidance to optimize machinery performance and reduce downtime. Reach out via salesjake@lqysbearing.com or WhatsApp at +8618013237311 to discuss requirements and secure reliable bearing solutions.