Reduzir ruído e vibração: O papel dos ursos de rodas modernas no conforto em viagem

2025-10-24

Veículos modernos têm como objetivo uma viagem suave e tranquila. Recursos de rodas desempenham uma grande parte nisso. Esses componentes sustentam rodas enquanto cortam ruído e tremores. Os motoristas percebem a diferença imediatamente. Este artigo mergulha em como os comportamentos evoluíram e por que eles importam para o conforto.

Entender a fonte de ruído e vibração nos veículos

Ruído e vibração entram em carros de muitos pontos. - Os pneus atingem a estrada, os motores tocam, o vento corre. Mas as rodas? Eles podem amplificar essas questões se não chegarem a equilíbrio.

Como os ursos de rodas afetam a suavidade de condução

As rodas deixam as rodas girar livremente. Mas demasiada fricção envia vibrações diretas para a cabana. Pense nisso: um pequeno defeito no bearing pode agitar toda a roda de direção. A fricção rotacional aumenta. Ele transfere tremores através da suspensão. Rubricas suaves manter as coisas constantes. - São difíceis? Eles fazem cada batida sentir-se maior. Os engenheiros se concentram neste link porque atinge a qualidade do carro duro.

Pequenas falhas são muito importantes. Uma brincadeira na corrida eco como um tambor. - O ruído do cabine salta. Passageiros se queixam. Ela não é apenas irritante; Ele te cansa em viagens longas. Os ursos precisam lidar com cargas sem queixar.

causas comuns de ruído

A terra entra. Isso é um culpado alto. Contaminação se mistura com gordura, molhando partes juntas. - lubrificante incorrecto? O mesmo problema. - Os ursos secam, os resíduos de metal. O desalinhamento deixa tudo fora. As rodas se arrastam para um lado, os bearings usam desigualmente.

Usar aparece como picar. Bolas ou rolos ficam cicatrizados com o tempo. - Altas milhas, estradas ruins aceleram. - Ouve por brincar à velocidade. Ou molhar quando girar. Esses sons sinalizam problemas. Peguem cedo para evitar melhorias maiores.

Às vezes ele é a instalação. Muito forte, ou não suficiente. Os ursos se ligam ou se soltam. O ruído segue.

A ligação entre NVH (ruído, vibração, dureza) e Design de Bearing

NVH significa ruído, vibração, dureza. Os fabricantes de carros são obcecados por ele. Usam micrófonos e sensores para medir tremores em laboratórios de testes. NVH baixo significa um sentimento primário. Os carros de alto nível se orgulham de cabanas tranquilas.

Portando design corta NVH. Toleranças mais rigorosas significam menos brincar. Superfícies mais suaves reduzem ruído de fricção. Melhor NVH aumenta como os motoristas avaliam o carro. - Parece sólido, refinado. Os ursos baratos deixam entrar vibrações, diminuindo essa percepção de qualidade. Já notaste como alguns carros econômicos batem mais? Muitas vezes, ele é que os bearings deslizam no design.

A evolução da tecnologia de carregamento de rodas

Os ursos chegaram longe. Os tipos de velhas escolas precisavam de adaptações constantes. Agora? Eles são mais inteligentes, mais duros.

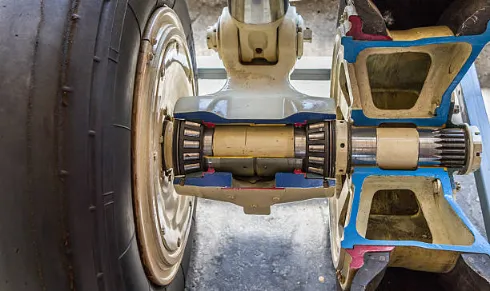

Desde Bearing Tradicional Tapered a Unidades Integradas de Centro

Recursos tapeados eram básicos. - Dois cónus, pré-carga ajustada. Eles trabalharam, mas a manutenção era um problema. Paquetes de gordura, selos para verificar.

Unidades integradas de centros mudaram o jogo. Tudo é fechado em um pedaço: carregamento, centro, às vezes sensor ABS. - Instalação mais fácil, não precisam de ajustes. Toleranças mais rigorosas da fábrica. Menos chance de erro. Essas unidades também duram mais. Os carros rodam mais suavemente sem a velha burbulla.

Unidades de centro cortam o tempo de montagem em linhas. Isso é grande para os fabricantes. Os motoristas obtêm confiabilidade sem a arma de gordura.

Materiales Avançados para Operação Quieta

O aço tornou-se mais puro. - Ligações de alta puridade resistem à fadiga. As bolas cerâmicas são mais leves, correm mais frias. Configurações híbridas misturam aço e cerâmica para melhores resultados.

A corrosão comer velhos lugares. Novos revestimentos lutam contra a raíz. Vias de corrida mais suaves significam menos ruído dos elementos de rolamento. - Os fins são como espelho agora. Isso reduz a transfer ência de vibração.

A cerâmica brilha em aplicações de alta velocidade. Os veículos elétricos os adoram. menor acumulação de calor.

Improvements in Precision Manufacturing and Sealing

A microfinalização é a chave. As superfícies são polidas para pequenas tolerâncias. Não há pontos difíceis para o ruído começar.

Seals evoluiu também. Desenhos multilábios bloqueam terra, água. Eles mantêm gordura dentro, contaminantes fora. As focas mais antigas vazaram mais facilmente. Os modernos selam firmemente, mesmo na lama.

Essa combinação silencia as coisas. Os ursos correm silenciosamente mais tempo. Fabricas usam máquinas CNC para ataques exatos.

Estratégias de engenharia para reduzir ruído e vibração

Designers tackle noise head-on. It’ é sobre lubrificante, apto, equilíbrio.

Lubricação óptima

A gordura importa. A viscosidade direita manipula o calor sem finar. Tempos estáveis evitam quebra.

lubrificante limpo evita contato com metal. Isso é onde o ruído começa: peças em bruto. A gordura sintética dura em extremos. Eles fluem melhor, abrigam uniformemente.

O excesso de lubrificação pode causar quedas e aquecimento, enquanto o excesso de lubrificação pode causar desgaste de pontos secos. O equilíbrio é tudo.

Controlo de pré-carga e alinhamento

A pré-carga estabelece a tensão. Muito soltos, os bearings mudam e hum. Muito apertados, eles exageram e molham.

O alinhamento assegura mesmo carga. Os centros crooked estressam um lado. O ruído construi. A adequação no centro mantém as coisas centradas.

Instalar ferramentas ajudam. As especificações do momento são estritas. Salta-os, e sons entram.

Balanço Dinâmico e Precisião da Assembleia

Montações de equilíbrio de fábricas. Os testes de rotação capturam desequilíbrios. Os sensores de vibração têm problemas cedo.

Ferramentas de diagnóstico simulam estradas. Eles medim tremores antes de enviar. A montagem de precisão usa robôs para a coerência. As mãos humanas podem variar, mas as máquinas as pegam todas as vezes.

Isso captura problemas pré-instalação. - Viagens mais suaves do primeiro dia.

O fator do conforto: Por que os ursos silenciosos são importantes para os motoristas

Os lugares silenciosos são: não apenas palestras tecnológicas. - Eles fazem motores melhores.

Cabin Comfort and Driver Perception

Menos vibração significa lugares confortáveis. Não há tremores distraendo você. O foco fica na estrada.

Os consumidores esperam silêncio agora. Luxuro ou não, os carros devem se calar. Os ruídos arruinam isso. Ela é como uma pista sonora ruim para seu viagem.

Benefícios de longevidade e segurança

O ruído avisa de fracasso. Ignore-o, os bearings capturam. Isso é perigoso à velocidade.

Os confiáveis cortam a manutenção. - Menos visitas à loja. - Ligações de segurança: rodas estáveis lidam melhor.

A vida longa significa paz mental. - Carregam as últimas 100k de quilômetros? Ouro.

Eficiência de combustível e tratamento suave

A baixa fricção economiza gás. As rodas giram mais facilmente. - A eficiência sube.

O tratamento suave segue. Não há pulsos ou burbujas. Torna-se crisp. Ela estão todos conectados.

Os carros elétricos beneficiam especialmente. Os comboios silenciosos destacam o ruído de carregamento se não for abordado.

Yongheshun's Approach to Low Noise Bearing Design

YongheshunCity name (optional, probably does not need a translation), um fabricante baseado em Xangai, foca em posições de alta precisão. Eles produzem colocações de bola profundas e tipos de blocos de almofada, enfatizando qualidade.

Máquina de precisão e controle de materiais avançados

Yongheshun assegura tolerâncias uniformes. Sua máquina atinge microníveis para terminações suaves. Os materiais são controlados rigorosamente: aço de alta pureza para durabilidade.

Esta configuração minimiza o ruído desde o início. Até as corridas reduzem a vibração. Eles lidam com exportações, então padrões são globais.

Testes rigorosos de NVH e Endurance

Os testes são fundamentais. Os controles da NVH medim ruído sob carga. A duração corre simulando milhas.

Os métodos incluem testes de rotação, análise de vibração. O desempenho se mantém em calor, frio. Isso elimina desenhos fracos.

Soluções de Bearing Personalizadas para Aplicações OEM

tailors Yongheshun para OEMs. Os EVs obtêm opções de baixa fricção. - Carros de passageiros? - Centros silenciosos. Veículos pesados precisam de veículos robustos.

Desenhos adequam necessidades específicas: contato angular para precisão. Ela é acerca de concordar com o aplicativo.

Conclusão

Ruas modernas cortam ruído e vibração, aumentando o conforto de viagem. Design de qualidade lida com a fricção, fecha os problemas. Os motoristas gostam de viagens mais suaves e quietas. Fabricantes como Yongheshun entregam com precisão e testes. Para a confiabilidade, escolhem lugares engenhados. Eles pagam em conforto e longevidade.

FAQ

Q1: O que causa o ruído de rouas mais frequentemente?

Contaminação ou uso. A terra se mistura, ou as partes cavam ao longo do tempo. Humming à velocidade é uma pista.

Q2: Como os comportamentos modernos diferem dos antigos?

Eles são centros integrados, mais fechados. Menos manutenção, mais ataques.

Q3: Por que testar NVH?

Para medir ruído e tremores. NVH baixo significa melhor sentimento do veículo.

Q4: Podem os ruídos afetar o uso de combustível?

Sim. Mais fricção desperdiça energia. Os suaves economizam gás.

Q5: O que faz com que os bearings Yongheshun se destaquem?

Máquina de alta precisão e controle material. Adaptado para vários veículos.