16 Types of Vehicle Bearings Used in Automotive Applications

2026-01-29Definition of Vehicle Bearings

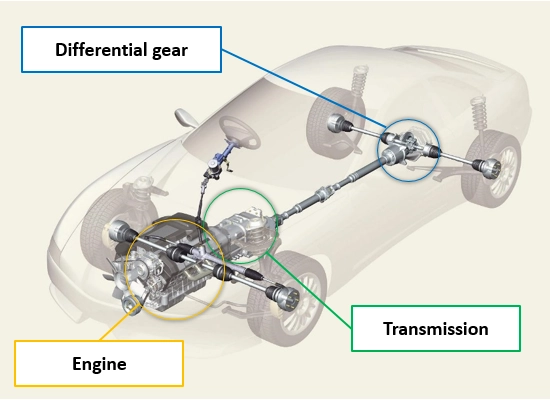

Vehicle bearings are key mechanical parts in cars and trucks. They cut down friction between moving pieces, hold up spinning or straight-line movement, and spread out weight well. These parts help important vehicle systems run smoothly and without much trouble. This includes wheels, transmissions, suspensions, and engines. Vehicle bearings come in many kinds. Each one is made for certain jobs and load needs, like ball bearings, roller bearings, needle bearings, and angular contact bearings. They play a big role in how well the vehicle works, how long it lasts, and how safe it is. They let parts such as wheels, shafts, and gears move with less drag and very little wear.

Bearings form important pieces in car engineering. They give needed support and make movement easy in lots of vehicle areas. Many bearing types work in the auto world. Each one fits exact needs for function. The parts below list 16 types often used as vehicle bearings.

Different Types of Vehicle Bearings

1. Ball Bearings

Function: Шариковые подшипники use small round rolling pieces held between inner and outer rings. They lower friction and allow easy spinning. This setup deals well with both radial and axial loads. It works great for fast-turning uses.

Automotive Applications: Ball bearings show up often in wheel hubs. They let wheels spin with little friction, which helps the car move smoothly. They also appear in alternators, water pumps, and gearboxes. There, high spin speeds and low friction matter a lot.

2. Roller Bearings

Function: Roller bearings have cylinder-shaped or tapered rollers. These spread loads across bigger contact spots. They handle heavier radial and axial loads than ball bearings. Yet they keep friction low.

Automotive Applications: Tapered roller bearings matter a lot in wheel hubs. They carry the vehicle’s weight and deal with forces from speeding up, slowing down, and turning. They also hold up differential systems and transmissions. Those need strong load handling and long life.

3. Needle Bearings

Function: Needle bearings have thin, long cylinder rollers. Their length-to-diameter ratio is high. This gives strong radial load support in small spaces.

Automotive Applications: Needle roller bearings fit into gearbox shafts, rocker arms, connecting rods, and compressors. Their narrow shape works well in tight spots. These spots need good radial strength in transmissions and engine parts.

4. Thrust Bearings

Function: Thrust bearings focus on axial load support. They stop axial shifts. They come in ball thrust and roller thrust styles to fit certain load and speed needs.

Automotive Applications: Thrust bearings do important work in clutch release setups. They handle axial loads when the clutch engages or releases. They also show up in some gearbox builds to push back axial forces from gear work.

5. Spherical Bearings

Function: Spherical bearings handle angle misalignment with spherical surfaces on inner and outer rings. This allows bend in motion directions.

Automotive Applications: These bearings go on suspension parts like control arms and strut mounts. They soak up shocks and manage moves in many directions. This gives better stability and comfort on bumpy roads.

6. Plain Bearings (Bushings)

Function: Plain bearings, or bushings, offer a low-friction slide surface between parts. They use materials like bronze or polymers instead of rolling pieces.

Automotive Applications: Plain bearings hold suspension systems in control arms and sway bars. They also work as engine connecting rod bushings and chassis pivots. This allows smooth slide action without fancy rolling setups.

7. Angular Contact Bearings

Function: Angular contact bearings handle mixed radial and axial loads. They direct forces at an angle. This gives more load strength than regular ball bearings.

Automotive Applications: These bearings often sit in front wheel hubs. They manage vehicle weight (radial) and side forces from turns (axial). This boosts stability, handling, and overall performance.

8. Tapered Roller Bearings

Function: Tapered roller bearings use cone-like rollers. They spread loads well and do great under heavy mixed radial and axial conditions.

Automotive Applications: These bearings rule in wheel hubs, transmissions, and differentials. They give sharp steering and lasting strength in tough load cases. Examples include off-road vehicles and heavy-duty trucks.

9. Cylindrical Roller Bearings

Function: Cylindrical roller bearings focus on high radial load strength with some axial help. They offer low friction and fit high-speed work.

Automotive Applications: They appear often in electric motors, transmissions, alternators, gearboxes, and crankshafts. These bearings give steady radial support and good work at high speeds.

10. Self-Aligning Ball Bearings

Function: Self-aligning ball bearings have two rows of balls and a spherical outer raceway. This fixes shaft misalignment.

Automotive Applications: These bearings fit steering columns and some suspension parts. Those parts face alignment changes. They keep things running smooth even with small shifts.

11. Magnetic Bearings

Function: Magnetic bearings use magnetic fields to hold spinning shafts without touch. This removes friction for fast, low-maintenance work.

Automotive Applications: They start to show up in electric vehicles and turbochargers. Magnetic bearings allow no-friction action in fast-moving parts.

12. Journal Bearings

Function: Journal bearings have lubricated cylinder sleeves. They support shafts with sliding motion and stay strong under big loads.

Automotive Applications: These bearings hold engine crankshafts and camshafts in regular engines. They manage high pressures well.

13. Linear Bearings

Function: Linear bearings allow low-friction straight motion along a line. They differ from spinning types.

Automotive Applications: Linear bearings help with seat moves and sliding door setups. Those need exact straight-line action.

14. Clutch Release Bearings

Function: Clutch release bearings deal with axial loads in clutch engage and disengage steps.

Automotive Applications: They matter in manual transmissions. These bearings make shifting smooth by cutting friction and holding axial forces.

15. Hydrodynamic Bearings

Function: Hydrodynamic bearings build a lubricant layer between surfaces. This gives low-friction work at high speeds and heat levels.

Automotive Applications: They mainly go in turbochargers. These bearings work well in tough settings beyond normal rolling bearings.

16. Air Bearings

Function: Air bearings use pressed air layers for almost no-friction motion.

Automotive Applications: They mostly appear in special test gear and trial car setups. Those need very exact and smooth action.

Вывод

Vehicle bearings act as basic parts that push car system efficiency, trustworthiness, and long life in different conditions. The wide mix of bearing types, each tuned for specific tasks, helps better vehicle work and safety. Regular ball bearings allow easy wheel and alternator action. Strong tapered roller bearings stand up to big loads in transmissions and differentials. Needle bearings give small high-load fixes in transmissions. Thrust bearings provide exact clutch handling. Spherical bearings boost suspension flex. Plain bearings cut slide friction in chassis spots. Angular contact bearings build strong wheel steadiness in motion. Choosing and using these bearings right stays vital for vehicle trust and drive feel. New changes in bearing materials, seal methods, and low-friction builds keep meeting new needs in regular and electric cars. This includes better lasting power, lower energy use, and improved NVH levels.

Часто задаваемые вопросы (FAQ)

What define vehicle bearings and their primary role in automobiles?

Vehicle bearings cut friction, hold motion, and spread loads in car systems. They affect performance, efficiency, safety, and part life directly.

Which bearing types most effectively support heavy combined loads in wheel hubs?

Tapered roller bearings and angular contact bearings do best in wheel hubs. They handle big radial and axial forces from vehicle weight and turn forces.

Do magnetic or air bearings appear frequently in conventional vehicles?

These advanced kinds mainly fit electric vehicles, turbochargers, or special tests. They do not show up much in normal production cars.

How do needle bearings contribute to transmission performance?

Their small size and high radial load strength fit tight areas. This makes them perfect for gearbox shafts and other close high-load spots.

What key considerations guide bearing selection for automotive applications?

Factors cover load kind and size, spin speed, install room, work heat, outside conditions, needed life span, and service times.

Partner with a Leading Manufacturer and Seller for Premium Vehicle Bearings

Automotive manufacturers, OEM suppliers, aftermarket distributors, and industrial partners seeking reliable, precision-engineered bearings for vehicle applications can depend on Подшипники LQYS. As a dedicated manufacturer and seller, LQYS Bearings (operating under Shanghai Yongheshun Import and Export Co., Ltd.) produces and supplies high-precision, high-quality automobile bearings, including angular contact ball bearings, tapered roller bearings, needle roller bearings, cylindrical roller bearings, ball bearings, and more. These products address wheels, transmissions, engines, steering, and other critical systems with enhanced safety, superior durability under vibration and shock, reduced maintenance, improved fuel efficiency through low-friction designs, quiet NVH performance, compact solutions for space-limited installations, and reliable operation across wide temperature ranges (-40°C to +150°C). With a 12,000 m² facility, advanced production processes, modern testing equipment, and exports to over 30 countries, LQYS Bearings supports OEM and aftermarket demands globally. Свяжитесь с командой for custom solutions, quotations, or collaboration opportunities via email at salesjake@lqysbearing.com, telephone at +8613002187311, or WhatsApp at +8618013237311.

Предыдущая: why-choose-needle-roller-bearings

Следующий : топ-10-подшипников-производителей-вы-должны-знать